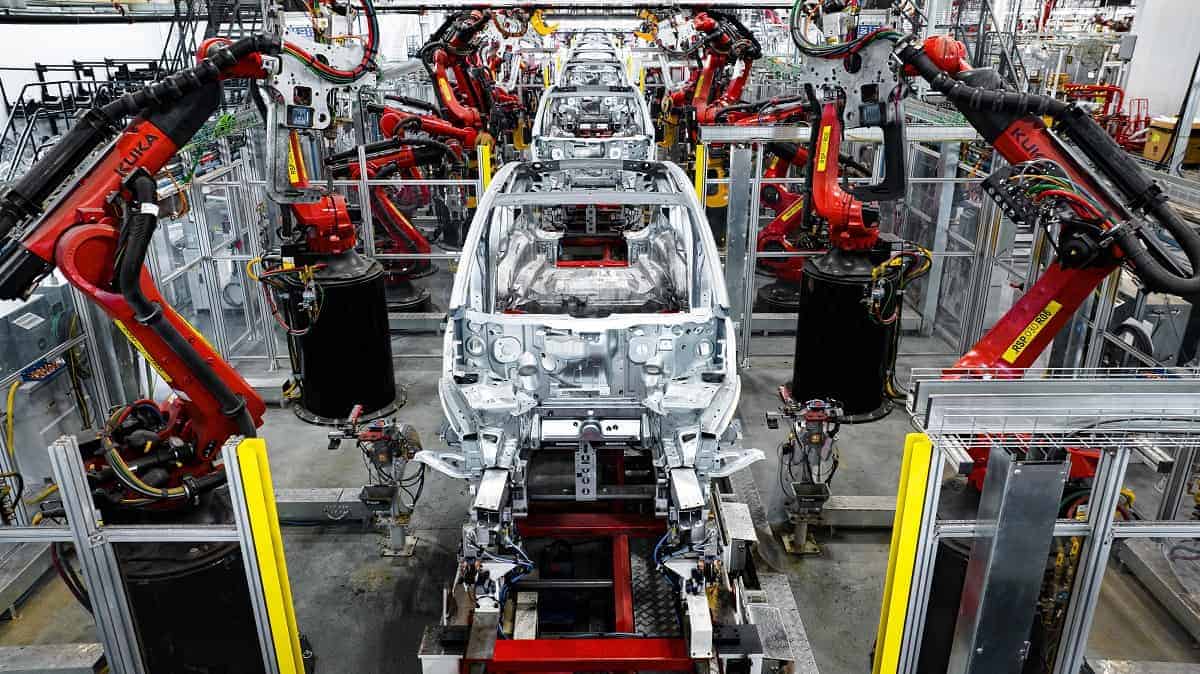

Tesla Assembly Time May Be Reduced by 25% with New Models

Tesla assembly time will be reduced by 25% with new models, according to engineering services company Caresoft Global Technologies. It also believes that in the future, capital investment in factories and their footprint will be reduced by 30%.

Tesla assembly time will be reduced by 25% with new models

Caresoft Global Technologies, a Michigan-based engineering company specializing in digital and physical benchmarking and cost reduction, recently released its report on Tesla. According to its findings, the time the company spends assembling cars will be reduced by 25 percent in upcoming updated models. The firm believes that Tesla will continue to improve the manufacturing process. This is exactly what will lead to increased efficiency and reduced production costs.

Capital investments and the footprint of factories will be reduced by 30%

Caresoft Global Technologies also predicts a 30 percent cut in Tesla’s capital investment in its factories. The company is constantly trying to optimize the production process by making improvements to its factories, production technologies, and the cars themselves.

Also, according to Caresoft Global Technologies, continuous improvement will result in Tesla achieving significant reductions in manufacturing space. It is expected that the reduction will be made by 30 percent. At the same time, the efficiency of painting shops will increase.

Tesla is committed to innovation

The Texas-based manufacturer is a model in today’s automotive industry. While legacy manufacturers are reluctant to keep up with the times, Tesla is the industry’s benchmark. The company is constantly inventing something new in an effort to reduce the cost of production and improve the quality of its cars.

Along the way, Tesla not only makes cars, but also the factories that make them. The company has the most efficient factories in the world and no other automaker can compete with the innovative Tesla.